In this guide, we'll outline everything you need to know about how to start a dropshipping business, from choosing a lucrative product niche to figuring out the demand for products, and choosing an ecommerce platform to running the right marketing campaigns to bring in customers.

In addition, we talk about if a print-on-demand shop is right for you, along with other questions about the legality of dropshipping, how much money you need, and more.

Keep reading to learn all about how to start a dropshipping business the right way.

In this article

How to Start Dropshipping? The Steps Required:

- Choose a Lucrative Product Niche for Your Dropshipping Business

- Decide if You'd like to Create Custom Print-on-demand Products to Dropship

- Select an Ecommerce Platform and Build Your Store

- Choose a Supplier That Dropships

- Run Marketing and Advertising Campaigns that Work Specifically for Dropshipping

- Handle Essentials like Permits and Taxes

- Continuously Optimize Your Site

💡 Note: Are you ready to learn how to start a dropshipping business? If so, remember that dropshipping is simply a form of fulfillment method. It's still a full-fledged business where you must put in a considerable amount of work with website customization, product sourcing, customer support, and more.

We encourage you to avoid dropshipping as a “get rich quick scheme,” since it's far from that in any way.

Step 1: Choosing a Lucrative Product Niche for Your Dropshipping Business

I've seen far too many people write blog posts or request advice on forums on how to find “ideal” dropshipping products.

I have some news for you: There's no secret recipe that's being hidden by all of the successful dropshippers out there. They simply went through steps to locate products they may enjoy, have great shipping times, solid margins, and have found success in the past.

Dropshipping puts you in the position of a middleman. That means the vast majority of the products you can choose from have been sold in the past, are currently being sold, and will continue to be sold by others. You're not going to stumble upon some hidden invention before everyone else gets their hands on it. Suppliers are selling all sorts of products, from wireless earbuds to wigs, and essential oils to luxury leather bags.

The key is to avoid making a “General Store” and instead find a unique selling proposition with a few useful, everyday products.

What does that mean? Here are some steps to help you get there:

- Look around your own life and figure out what interests you, or something you can get into. For instance, I play softball every Tuesday, like going to the movies, and ride my bike or go camping on the weekends. Those are four huge categories that I can start looking into. All of them have wonderful products for dropshipping.

- Narrow it down to a specific market, or something special. Sometimes you must test these out to see if there's any interest, but the idea is to take a general category, like camping, and narrow it down to a group with certain needs. For instance, maybe I could sell to female campers? Maybe I could only sell stylish hiking bags to female campers who also want functionality like a place to put their water, clothes, and maybe a toiletry bag?

- Research keywords to see if anyone's looking for this type of stuff. Go to Google Trends, Google Keyword Planner, and the various other search engine analysis tools and start testing out keywords that may apply to your niche. This gives you some perspective on the competition and how much traffic comes in for those words.

- Check places like Reddit, Facebook, and YouTube to see if people are talking about these products for those types of people.

- Finally, we want to make sure the idea is lucrative. This is when you go into apps like Spocket, Modalyst, or AliExpress to see what margins look like for new products in the category.

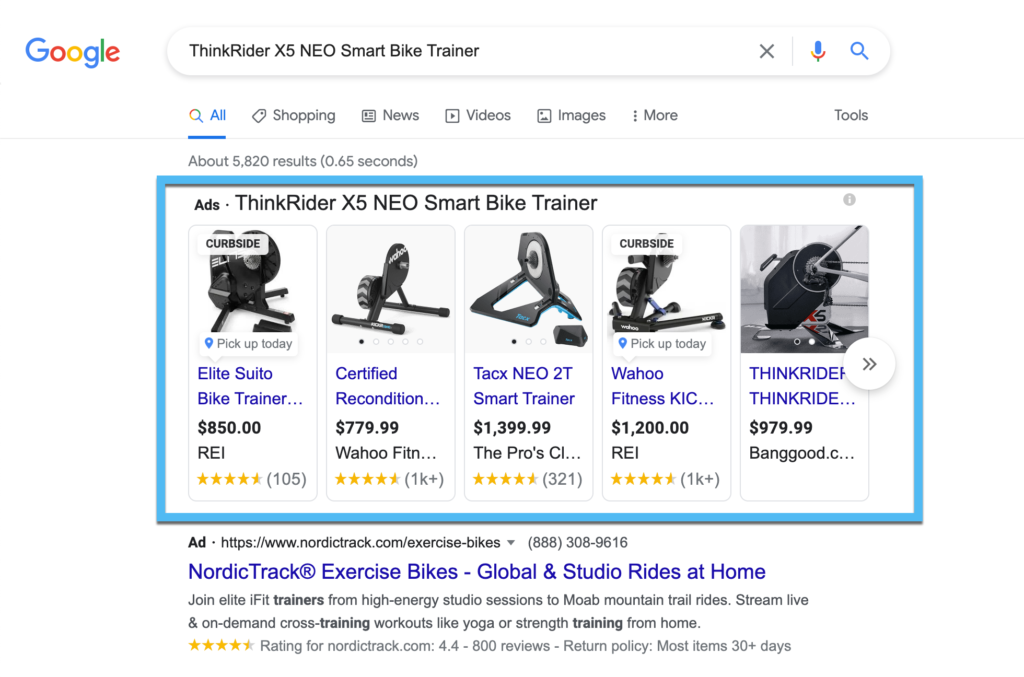

As an example of checking the profit potential for a product, I found this bike trainer that costs anywhere from $460 to $627. That's the cost that you, the merchant, would pay after making a sale.

And a quick search for similar, or comparable bike trainers shows price listings of anywhere from $700 to $1,400. At a minimum, your profit could end up at around $70 per sale. That's not bad, but the higher price ranges could produce close to $1,000 in profit. Keep in mind that this is a higher-priced item to begin with, so a cheaper product, like a backpack, would still look like a high-quality choice if you could buy it for $20 and sell it at something like $50.

Step 2: Decide if You'd like to Create Custom, Print-on-demand Products for Your Dropshipping Store

The dropshipping world offers two means of sourcing your products:

- Standard dropshipping: With previously designed and created products, ready to be sold and shipped to your customers.

- Print-on-demand: A setup where you make certain designs and have them printed onto products once a customer orders them. Then, the print-on-demand supplier also ships out the item.

Printful is one of the most popular solutions to configure a print-on-demand dropshipping store.

This method has its advantages and downsides, but in general, print-on-demand dropshipping allows you to differentiate your brand from the rest, create entirely unique products, and still eliminating the need to store or ship your items. However, there's also extra work involved, since you have to make the designs.

Printful, and other print-on-demand platforms, let you upload designs to various types of products such as:

- Apparel

- Bags

- Phone cases

- Jewelry

- Keychains

- Shoes

- Pillows and blankets

- Coffee mugs

- Pet products

- Stationary

- Posters and canvas prints

- Much more

Further reading 📚

Step 3: Select an Ecommerce Platform and Build Your Store

An ecommerce platform serves as a way to build an online store and a complete website all in one place. These platforms offer features for creating product pages, collecting payments for your sales, and even completing marketing tasks like social ads and email marketing.

Therefore, it's essential to get set up with an ecommerce platform, since it's the main way you'll sell your products as a dropshipper.

We like Shopify the best when learning how to start a dropshipping business since it offers some essentials you can't find anywhere else.

Why Shopify is the Best for Dropshipping

- It offers premade templates for various industries, allowing you to design a professional-looking online store within minutes.

- The payment processing is free (besides credit card processing fees) and integrated directly into the platform.

- Shopify integrates with a wide range of dropshipping and print-on-demand apps like Spocket and Printful.

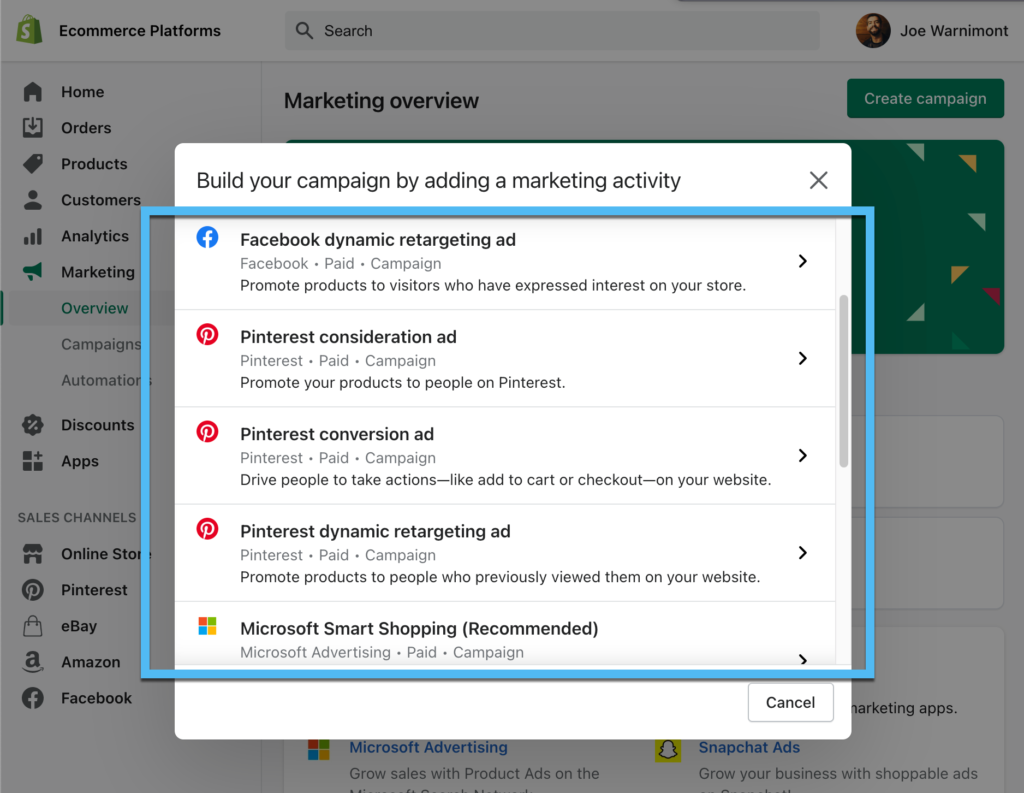

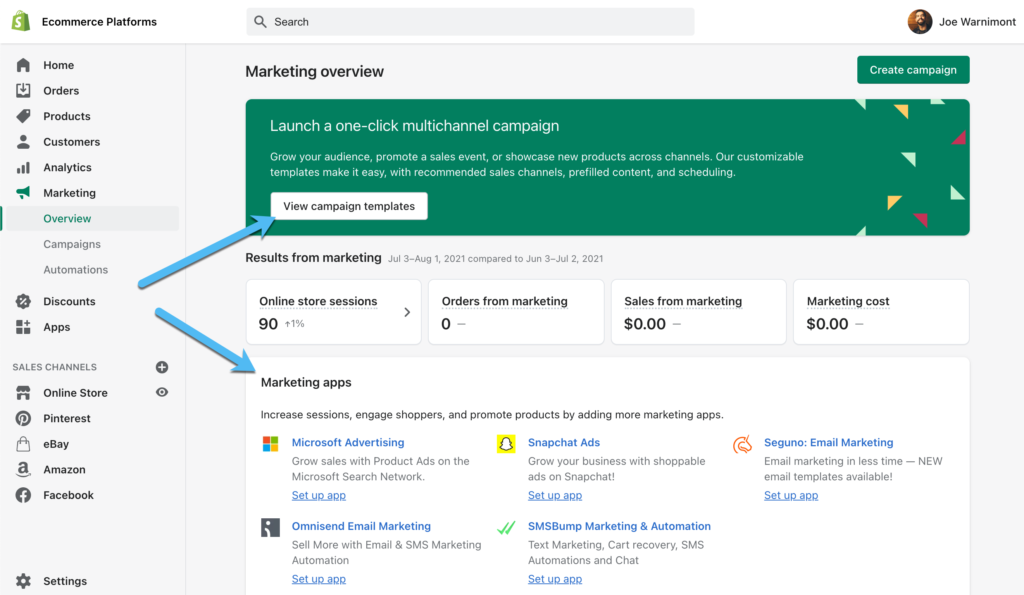

- Shopify has superior advertising tools for launching ads on places like the Microsoft Search Network, Google Search, Facebook, Snapchat, and more. Advertising is the main way you bring in sales for dropshipping, and no other platform has this many advertising options.

- You can start selling your dropshipped products on places like eBay and Amazon.

- They let you almost instantly make a Facebook Shop, which is great for dropshipping.

- Shopify has various automations for bringing back dropshipping customers like email marketing workflows and abandoned cart emails.

Read our guide here on how to configure a Shopify store in less than 15 minutes. You can go to the Shopify website to start a free trial for 14 days, then walk through the steps of linking a dropshipping app, adding product descriptions, linking your payment gateway, and designing the shop.

Other Ecommerce Platforms that Work for Dropshipping

- Wix: About as simple as Shopify for dropshipping, but not as many advertising tools.

- BigCommerce: Offers a wonderful interface for dropshipping. The main dropshipping apps are Spocket and Printful, so it's solid but limited compared to Shopify.

- WooCommerce: You can integrate with just about every dropshipping app but WooCommerce runs on WordPress and requires more technical knowledge.

- Magento: Similar to WooCommerce, where you gain complete control over the site but technical knowledge is usually required.

- OpenCart: Requires some technical knowledge, and it has a few decent AliExpress dropshipping apps.

Further reading 📚

Step 4: Choose a Supplier That Dropships

As mentioned before, you don't have to get on the phone anymore to start calling suppliers in your desired industry to make it as a dropshipping professional. In fact, that's probably a waste of time, unless you'd like to get really specific with the type of product you want to sell and where it's coming from.

Several reputable dropshipping apps are available that integrate with Shopify and the many other ecommerce platforms.

These dropshipping apps provide:

- A full marketplace for finding suppliers and products

- Filtering tools to hone in on specific categories

- Information like the cost of products, potential margins, and sales

- Instant syncing with your ecommerce platform to transfer product details, photos, and pricing

- Automated messaging to the supplier (and you) when an order comes in through your store

- Direct linking with everything your ecommerce store offers, like stats, marketing, and social ads

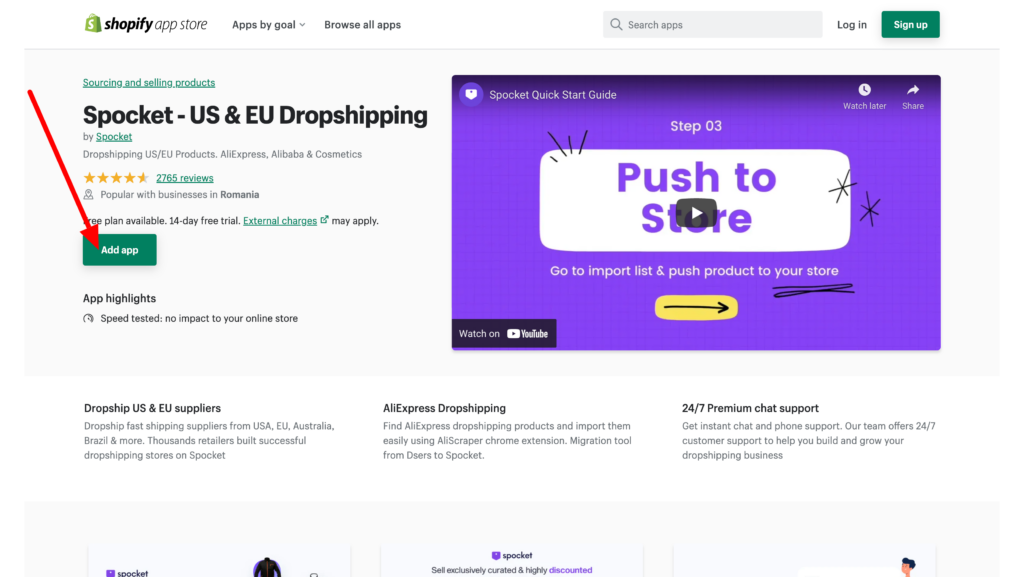

Start Your Journey With Spocket

Spocket is the most effective dropshippping app for all skill levels, considering it links you to AliExpress, which has the largest collection of worldwide suppliers who dropship.

Therefore, you can install the Spocket app on your Shopify store, and filter for products based on what you need.

We recommend filtering for things like shipping times, where the products get shipped from, and potential margins.

Some customers don't care if they have to wait a few weeks to receive a quality product. But in our experience, it's troubling when you see shipping times around 15 to 30 days. We encourage you to skip those products and opt for ones with shipping times ranging from 1-14 days to the country of your choice. It takes some digging but there are plenty to choose from. We also find that it's sometimes easier to find these faster shipping rates by directly browsing on AliExpress instead of Spocket.

Consider Printful for Print-on-demand Dropshipping

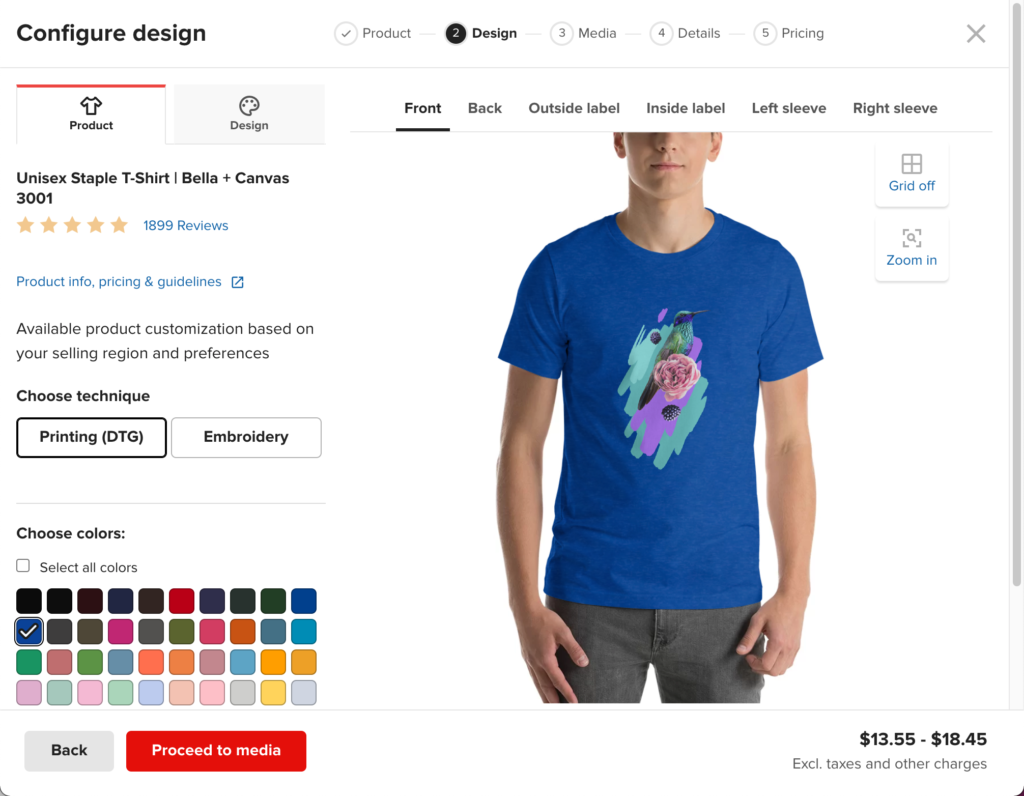

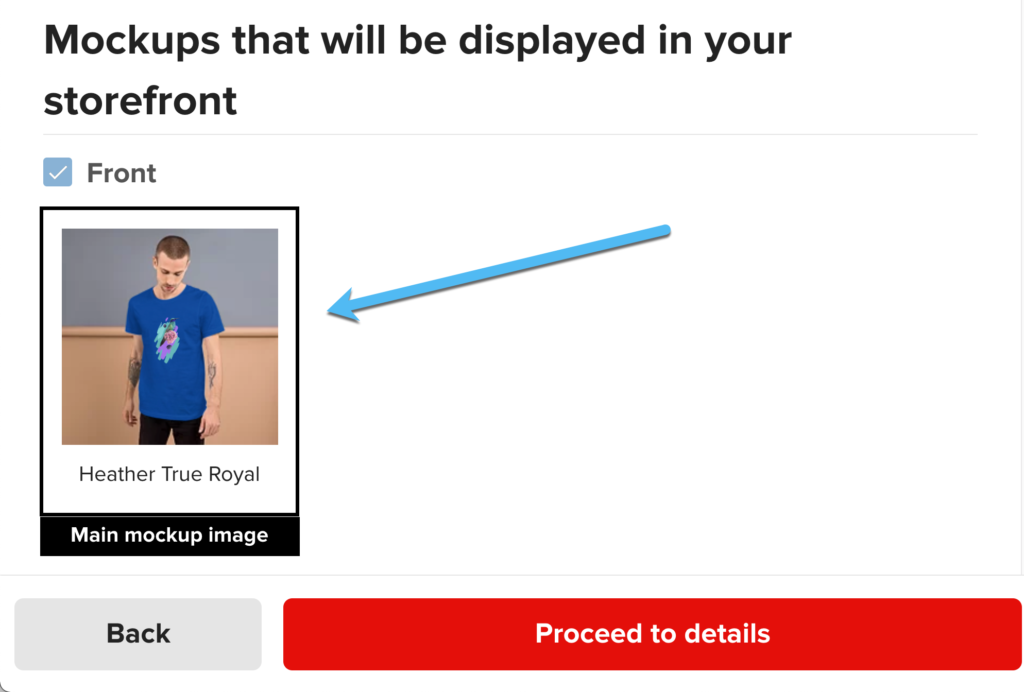

If you decide to go with a print-on-demand dropshipping store, the most practical app to install is called Printful. The company has a wide range of warehouses located around the world, so your customers receive faster shipping, and Printful maintains higher levels of quality control (since they own their warehouses).

Check out our complete guide on how to make a print-on-demand dropshipping site with Printful and Shopify.

In short, you create both Printful and Shopify accounts, link the Printful app to Shopify, then start uploading your designs to Printful. After that, you're able to choose products to place the designs on, set pricing for those products, and sync them with your Shopify store.

Not only that, but Printful offers beautiful product images where your custom-made designs appear on mockup pictures with human models.

Other Dropshipping Suppliers to Consider

Each of the following dropshipping apps has its pros and cons. For example, DSers and Modalyst specialize in dropshipping from independent suppliers and providing fast shipping to places like the USA, UK, and EU. Printify is an alternative to Printful, while some of the others are similar to Spocket with unique selling points.

- DSers

- Modalyst

- Printify

- Doba

- Salehoo

- Wholesale Central

- Dropified

- CJDropshipping

- Teelaunch

- SPOD

- CustomCat

- Apliiq

- EPROLO

- Syncee

- Gooten

- DropCommerce

Step 5: Run Marketing and Advertising Campaigns that Work Specifically for Dropshipping

As any experienced dropshipping professional will tell you, you won't see any sales until you establish a solid advertising plan.

Dropshipping is unique in that you're not as worried about building your brand (although you should do that as well) but more about testing ads, finding the ones with the best results, and retargeting to people who have shown interest.

Therefore, the following types of marketing and advertising strategies usually work the best for dropshipping:

- Facebook and social ads: Facebook and Instagram are the gold standards for dropshipping ads, but Shopify also provides options for advertising on places like Pinterest, Snapchat, and TikTok where you can also dropshiping video ads.

- Retargeting: The retargeting campaigns on Shopify and Facebook utilize algorithms and AI to serve up ads again and again after someone has shown some sort of interest in your products.

- Google Ads: Along with Microsoft Ads, these give you a chance to get your product in front of people browsing around on search engines. Although very competitive, the right products and keywords can help you out quite a bit.

- Content marketing: Think about making videos, blog posts, and other content that features your products, shows pictures and videos of them in use, and explains details about how to use the products to your customers.

- Communities: Although you don't want to spam communities, it's not a bad idea to become active in forums, Facebook Groups, or Reddit threads that talk about your products. You may occasionally be able to mention your website if it comes up.

- Influencer marketing: Many dropshippers swear by influencer marketing, seeing as how these people have built-in platforms, lots of people who listen to their every word, and it serves as a way to advertise on social media without having to pay for Facebook or Instagram ads. In short, people are more willing to listen to another person they admire than a random ad on Facebook.

- Selling on marketplaces: This is more of a secondary way of selling, but places like Amazon and eBay also tend to bring exposure to products that perform well or get quality reviews.

Step 6: Handle Other Essentials for a Dropshipping Store

Dropshipping presents one of the simpler types of fulfillment, but that doesn't mean you can skimp when it comes to properly and legally setting up your business.

Here are some other essentials to consider as you learn how to start a dropshipping business:

- Get your permits and licenses. Check your local laws to figure out if an online store needs standard permits or special business licenses to conduct business in the area. In general, this is almost always a requirement, so the last thing you want is to be running an illegal business.

- Establish a business structure like a Sole-proprietorship, C Corp, LLC, or S Corp. Take a look at the requirements in your region, and speak to the Small Business Association or related organization in your area.

- Get your finances and credit in order. Most payment processors (like the ones provided through Shopify) require a potential credit check or at least some sort of proof that you're able to reach a certain number of sales to make the partnership worthwhile. Make sure you have all of this squared away to make the approval process easier. Also, think about how much money you should be saving in order to pay for things like ads, taxes, and investing elsewhere in your business.

- Save money from your sales for taxes and paying the supplier. Not all revenue goes right in your pocket. A quick way to wreck your business is by taking all the money and forgetting that you must pay for taxes and the products themselves.

The Pros and Cons of Dropshipping

What are the benefits and downsides of learning how to start a dropshipping business? Here's a look into the main ones:

Dropshipping Pros 👍

- The products are already made for you: There's no wait time on a supplier that needs to manufacture a batch of wholesale goods for your company. And although some customization is available through dropshipping, you're usually partnering with a supplier that already has products. Therefore, you wouldn't dropship if you invented a product. Keep in mind that print-on-demand suppliers are a huge exception. You can design items like shirts, mugs, and canvases with partners like Printful. The raw product is already created but then they print on it with your own design.

- The upfront and overhead costs are incredibly low: Dropshipping has a low barrier to entry, even for those who aren't flush with startup capital. In fact, you can start a dropshipping business with almost no money at all. That's a bit of a stretch since you must pay for an ecommerce platform and advertisements, but small amounts of money go a long way with dropshipping. Also, think about the savings by eliminating warehouses, shipping materials, warehouse employees, and the various other elements that go into the logistics of fulfillment.

- You can turn a profit quickly when learning how to start a dropshipping business: An ecommerce platform starts at around $29 per month. Let's say you spend $100 on advertisements for the first month. That means you only need a profit of $129 to break even. That's obviously a simplified view of it, but dropshipping costs are so low that advertising usually comes in as the highest expense.

- You're protected from unpredictable sale trends: One of the primary downsides of wholesale buying is that you purchase a large batch of products and wait for people to buy them from you. That's a huge risk considering that trends change, seasonality comes into play, and you may find that you overbought on the inventory. Dropshipped products get shipped out on-demand, meaning you're not left with a high upfront price tag that could potentially sink your business. Instead, you gradually grow your sales and never have to worry about inventory collecting dust on the shelves.

- You can spend most of your time and money on market research and selling: Resources for a dropshipping business go primarily to advertisements on Google, Facebook, and other social media sites like Instagram and TikTok. All of your hard work and investments go into that, making it a rather simplified, focused business model that many individuals are suited to handle.

- It's a nimble space: Are you finding that your product isn't selling well anymore? Simply choose another product in the same industry (or a completely different one) and start selling that. Although it takes a little time and some investment to pivot, you're not worrying about leftover inventory that you must sell.

- You don't have to store products or worry about inventory management: Dropshipping leaves the storage of products to the supplier. That's the main premise behind dropshipping, helping the merchant out by simplifying the logistics of the entire operation and cutting down on costs for warehousing, inventory management software, and workers.

- Packaging and shipping are left to the supplier: Not only are the products stored in the supplier's warehouse, but they package and ship the products for the merchant as well. Again, you (the merchant) now have no need to pay for warehouse workers or to set up a process of picking, packing, and shipping. You also save on any materials you would have to use for the shipments.

- There are plenty of platforms to launch a dropshipping operation and partner with a supplier within minutes: You have the option to directly contact suppliers and see if they'll dropship products for you. However, several ecommerce platforms and third-party dropshipping software allow you to sign up for an account and choose from large selections of products, all available for dropshipping. This gives access to more suppliers in one place, and your products sync with your ecommerce platform.

- You can now find dropshippers that ship to your customers in a reasonable amount of time: In the past, shipments took weeks, or even months, to get to their destinations when dropshipped. That's because the vast majority of products came directly from China. That has changed, with many dropshipping platforms offering warehouses in multiple locations like the US, UK, Europe, and Australia.

- You can still make a hefty profit with the right products: Dropshipping margins are lower than usual, but that just means you must put in a decent amount of research to locate products with respectable margins. You'll find that some items aren't worth messing with, but there are still plenty of options that sell for low prices but then consumers are willing to pay premium rates.

- It's often easier to manage high-maintenance products with dropshipping: Large, fragile, or technical products require special storage facilities and shipping materials. Because of that, it makes a lot of sense for the supplier or manufacturer to hold onto those types of products and send them out, instead of requiring a second company (you) to handle all of that when the items are passed off

Dropshipping Cons 👎

- The profitability is lower than other fulfillment methods: Dropshipping cuts out manufacturing, storage, and shipping. So you save money there. But that means the supplier takes a larger cut since they're completing all that work for you. The advantage of buying wholesale is that you can buy 10,000 units of a product for incredibly cheap, then mark it up for a hefty profit. Dropshipped products are sold on-demand, and the supplier does most of the work, so your margins get cut down significantly. Having said that, you shouldn't need as high of profit margins anyway since all you're doing is running an ecommerce website and marketing.

- It's harder to build a recognizable brand: Like many of the items you purchase on Amazon, there's a good chance you have no idea who's the seller. Dropshipping is similar to that, where the merchant gets less credit for the sale due to the fact that they're more of a middle-man, they don't have much control over the product and the shipping, and dropshipped products are often generic, non-customized items to begin with. Not to mention, you often can't put your label or logo on the package or drop an insert into the box to thank your customers.

- You may run into legal troubles: Not all suppliers play by the rules. You can go on a dropshipping site like Spocket, which connects you to suppliers on AliExpress (or Alibaba), and see hundreds of suppliers violating regional or national laws. And we're usually not talking about them selling illicit or dangerous materials, but rather those that are infringing on copyrights or trademarks. I've known dropshippers to get shut down because they sold Apple Watch bands that were too similar to what Apple offers. Or there was a dropshipper who sold light sword toys and marketed them as lightsabers, causing Disney to send them a Cease and Desist letter. (Surprisingly, you can sell them but not use the word “lightsaber.)

- There's limited product quality control and supply-chain control: Yes, you can absolutely order samples from your suppliers. But that's usually the extent to which you have control over your products. If an item comes off the line and it has a defect, you can't look at the product and decide not to ship it to your customer. Also, each step of the supply chain is left to the control of your supplier. Finding a reputable, reliable supplier solves most of these problems, but you must remember that you have limited control when it comes to shipping costs, shipping speeds, packaging materials, and the quality of those products going out.

- It's a highly competitive space: You have hardly any upfront costs! And that sounds amazing to optimistic entrepreneurs looking for an easy buck. Yet, dropshipping requires real work, since many of the products being sold are also marketed and sold by hundreds of other individuals and companies. After all, the supplier just wants to move the products, so if they'll dropship for you then they're probably dropshipping for several other companies.

- Some suppliers have absolutely terrible shipping speeds: As you can see in the Pros sections, this usually isn't a problem anymore as long as you complete your research and find the right suppliers. However, many suppliers are still located in China or India and take 30-40 days to ship to a place like the United States. That's unacceptable and a recipe for canceled orders in our world of expected 2-5 day shipping.

What is Dropshipping? And How Does it Work?

The term dropshipping refers to an ecommerce fulfillment method where a merchant partners with a supplier and that supplier makes, stores, and ships the products. Therefore, the merchants (or retailers) are not directly responsible for the overall movement of inventory. In fact, warehousing and shipping are all completed by the supplier.

The Supply Chain for Dropshipping

The simplest way to look at it is by listing the steps in which a product moves when processed through the dropshipping business model:

- The supplier buys or produces Product A.

- The supplier stores Product A in its warehouse.

- The merchant (you, the business owner) partners with the supplier through a dropshipping relationship.

- The merchant creates an online store for selling Product A.

- The merchant markets Product A.

- A customer purchases Product A from the merchant's store.

- Both the merchant and the supplier are notified of the sale.

- The supplier picks, packages, and ships Product A directly to the customer.

As you can see, the merchant (you, the store owner) doesn't actually see or touch the product throughout the entire dropshipping process. This cuts down on your own overhead and allows merchants to spend more time and money on marketing, building their websites, and expanding their own businesses instead of focusing on elements like warehousing, shipping, and packaging.

Overall, learning how to start a dropshipping business provides a significant amount of promise to those interested in eliminating the following:

- The need to have a storage facility.

- The need to purchase wholesale items.

- The need to run a picking and packing operation.

- The need to ship products out from your own location.

- And also the need to sometimes manufacture your own product (depending on what you're selling)

Quick FAQs on How to Start a Dropshipping Business

Is Dropshipping Legal?

Yep, as long as you source and sell products that don't violate any laws or infringe on any patents, copyrights, or trademarks. It's no different than any other business. Dropshipping actually isn't even an ecommerce business type, but rather a method of fulfillment within your business. So, as long as your business is following the rules you shouldn't have problems.

How Much Does it Cost to Start a Dropshipping Business?

The short answer to this is less than a regular online business where you purchase wholesale products, but also more than what many “experts” online say about dropshipping. There's an upfront time and monetary investment in order to configure your store, along with ongoing expenses to keep it running, present advertisements, and potentially hire people to help.

The most common dropshipping expenses include:

- A monthly subscription for an ecommerce platform like Shopify

- A domain name

- Advertisements

- Marketing apps

- Potential employees like virtual assistants or web designers

Below are some expenses from real, successful dropshipping websites listed for sale through Shopify's exchange.

Expenses from a novelty toy store:

- Shopify: $29 per month

- Domain: $14 per year

- Apps for marketing, currency conversions, reviews, and dropshipping: $49 per month

- Employees (a virtual assistant for customer support): $250 per month

- Instagram and Facebook ads: $4,000 per month

As you can see, the advertisements end up as the most expensive part, as is the case with the majority of dropshipping businesses. After all, that's how you bring in more customers. Keep in mind, however, that this business has average revenues of almost $40k per month. The expenses add up to about $4,329 per month. That's a $35k margin without factoring in the cost of goods sold. After that, this business reports an average profit of $8,400 per month.

Here's another real-world example from a yoga pants store on the Shopify Exchange Marketplace:

- Shopify: $29 per month

- Domain: $16 per year

- Apps for email marketing and more: $278 per month

- Ads on TikTok: $5,350 per month

- Cost of goods sold: $5,000

That's a total of about $10,658 per month in expenses. Again, most of those expenses are the ongoing ones that you don't necessarily have to worry about right from the start. This business has been growing for a while and increases its marketing spend each month. If you're curious, this particular dropshipping business brings in an average of just over $15k in profits per month. So the revenue gets close to $26k per month.

Can I Make Money Dropshipping?

Yes. See the previous question's examples.

Most money made from dropshipping comes from savvy business people who find useful, trending products (you're not reinventing the wheel), know how to create wonderful ads on social sites, and work full-time to grow their business.

Can I Dropship Products on Marketplaces like eBay and Amazon?

Yes. Both platforms allow for dropshipping. In fact, you've probably bought some dropshipped products from those sites in the past. Some platforms like Shopify and Wix even help you sync your dropshipped products with eBay and Amazon.

Do I Need to Pay for Shipping and Taxes While Dropshipping?

For taxes, most likely. Look up the local laws for your state, county, city, country, or wherever you live. Most of the time, you're required to pay taxes to the municipality where your home or office is located.

Shipping depends on your supplier. In my experience, most dropshipped products have some sort of shipping fee involved. Try to get the cheapest, fastest shipping for an advantage. If your supplier charges for shipping, simply figure out if you should pay for the cost yourself or pass it onto your customers.

Optimize Your Website like Crazy

As time goes on, it's wise to hone your website and further optimize it for keywords, improved media elements, and more creative product descriptions.

This is what we would call an ongoing task that you could outsource to someone else or simply work on it whenever you have free time.

And with that, you should be well on your way to learning how to start a dropshipping business and getting your first sale! But don't get discouraged if your first or fifth or tenth dropshipping product doesn't get the response you expected. That's the whole game behind dropshipping. Rigorous testing separates the amateurs from the true professional dropshippers. So get out there and start testing.

If you have any questions about how to start a dropshipping business, let us know in the comments section below.

Comments 0 Responses